Maximizing the Returns on Your Warehouse Automation

Is your warehouse struggling with shaky logistics, low efficiency, and poor OTIF (On-Time-In-Full) performance? Are you feeling the pressure to automate before the next peak season hits?

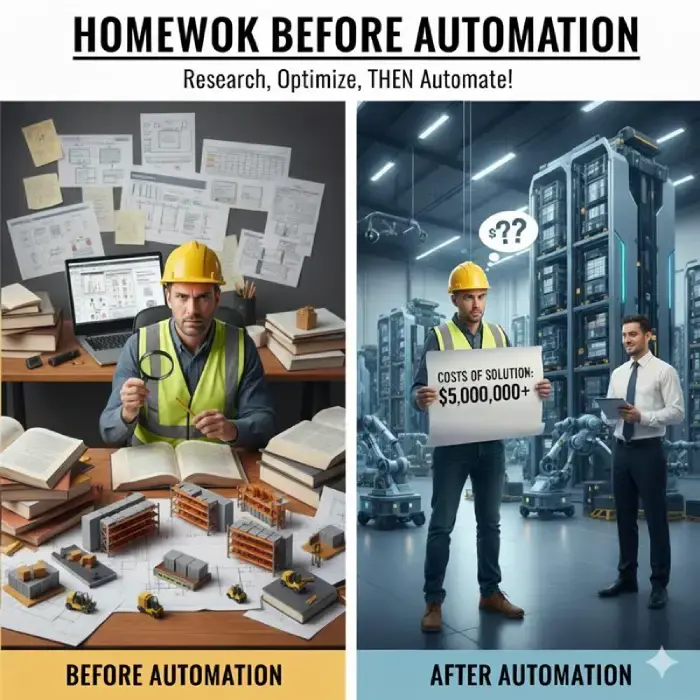

Automation can be a game-changer — but only if you prepare properly. What worked for your neighbor’s warehouse won’t automatically work for yours. Success in automation starts long before the first robot hits the floor. Here’s how to think and prepare for the journey.

1. Clean Up Your Current Processes First

Before jumping into automation, fix what’s broken in your manual operations. It’s tempting to assume automation will solve all inefficiencies, but that’s a costly misconception.

Boards and investors will (and should) challenge you on current process efficiency before approving a multi-million automation investment. The business case for automation always looks better when compared to an inefficient manual setup — but that’s exactly the trap.

If your calculations are based on poorly optimized processes, your investment will be built on sand. Take the time to streamline workflows, remove bottlenecks, and capture the “low-hanging fruits” first. Clean data and stable processes form the foundation for a solid automation ROI.

Badly researched investment assumptions always come back to haunt you — guaranteed.

2. Don’t Rely on Pick Rate Comparisons Alone

When comparing manual and automated performance, pick rate isn’t the only metric that matters.

In a manual warehouse, putting away a pallet is quick and cheap. But automation changes the equation — you may need to decant products into bins or totes, which introduces additional costs.

The right question isn’t just “How fast can I pick?” but “How many order lines do I pick per bin I fill — and what’s the combined cost of filling and picking?”

Analyzing this combined metric often reveals that not every SKU belongs in automation. Some item categories might be more cost-effective to handle manually. Making this distinction early prevents oversizing — and overspending.

3. Get the System Sizing Right

Sizing your automated system correctly is absolutely critical.Automated storage capacity is expensive. A single automated bin slot can cost several times more than a manual pallet position. That’s why not every piece of inventory needs to live inside your automation zone.

You might carry several weeks of supply for your high runners, but that doesn’t mean you should store all of it in the automated system. Smart design — knowing what to store where — can save millions.

At WHanalytics, we help clients calculate the optimal stock allocation for automated systems. With the right data-driven sizing model, you can strike the perfect balance between capacity, throughput, and cost efficiency.

4. Strengthen Manual Processes Around the Automation

Automation is powerful, but it’s only as strong as the processes that surround it.

Manual activities before and after automation — inbound buffering, decanting, order consolidation — can easily become weak links if not planned properly.

Establish clear strategies for what, how much, and when to replenish into your automation from your buffers. On the outbound side, consolidating picks from automated and manual zones is often one of the toughest challenges in modern warehouses. Quantify and plan these flows carefully to ensure your automation runs at full potential.

Final Thoughts

Successful warehouse automation isn’t about buying the flashiest system — it’s about building it on a solid operational foundation.

Optimized manual processes, a deep understanding of your material flows, and a data-driven investment case are what separate high-performing automation projects from costly disappointments.

Automation should enhance your warehouse, not compensate for inefficiency. Prepare thoroughly, analyze carefully, and let data lead the way — and your automation investment will deliver the returns you expect.

.webp)